June 14, 2023

This is a new port for us, and we foound out that it is the first time our ship has been to this port. When a new ship comes to a port, the local officials do a ceremony and present a placque to the captain. We were out on tour and didn’t see the ceremony but our friends happened to get off the ship when it was happening.

Amami Oshima is one of eight islands in the Amami archipelago, just some of the numerous islands that spot the stretch of sea between mainland Japan and Taiwan. There are steep tree covered mountain slopes. The island is far from the mainland and to this day, poor weather cuts locals off from food and important deliveries from the mainland. For any serious medical issue, they use helicopters to transport people to mainland hospitals. There are no colleges or universities here and when young people leave for post secondary education (as 96% of them do) most do not return.

Our guide today had a very long Japanese name, so he asked us to call him a short veresion – Kaz. He started off by saying that he works in an insurance office but when he is needed to serve as a guide he tries his best to do so. He said that he failed college entrance exams for a Japanese university four times, so he ended up going to colleage in Las Vegas, Nevada. He majored in hotel management and tourism. He loves this island, though, so he chose to come back to live and has been here for the 10 years since college.

The island has a long history. This town has a population of 50,000 people and the whole island has 100,000. Construction is the main industry and sugar cane production is second.

Our first stop was about 40 minutes from the port and it was Oshima Tsumugimura, a museum and factory tour where they have been making silk woven fabric for kimonos for many years. The site is beautiful. We walked through many tropical like settings with lush plants and beautiful flowers. Our guide here did not speak English, so Kaz interpreted on our tour.

We saw the first area, the dyeing house. Sharinbai trees are chopped into pieces and then steamed with water for 20 hours. The dyeing takes place for 20 times, Then the threads are set to dry. After that, they are dyed with mud fields and they turn into brown. This process is repeated 4 times. Finally, silk threads are changed into elegant black by dyeing 80 times. Fine mud fields contain tannic acid from the trees and the iron in the mud combined.

The pattern is designed by choosing the colors according to the graph paper pattern. Then, the Shime-bata loom is used to tighten the silk threads with cotton. To achieve the desired design, the cotton threads are removed so the silk threads may be dyed to match the specific color in the design. Finally, the fabric is carefully woven to match the pattern. Fine checking is performed every 8 cm where threads are adjusted to ensure accuracy and consistency. It takes a very long time to weave even a small section. A 5 inch section takes about 8 hours. This weaver is 74 years old and has worked there for 46 years. The factory has been there for 1300 years and now it is almost a dying art since like many occupations, the young people don’t want to do this anymore.

We visited the shop which had such beautiful products. Norm bought a shirt and I got a scarf.

There were hats, purses and all kinds of other accessories. But no kimonos for sale. We couldn’t have afforded one anyway.

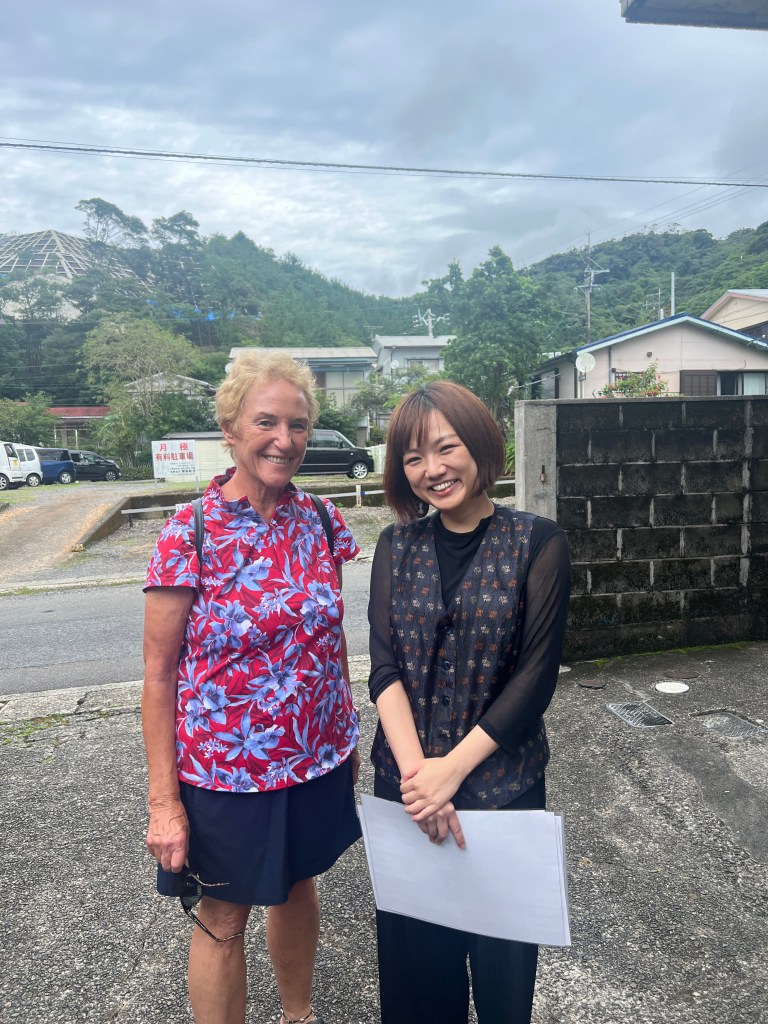

Our second stop was to the Shochu distillery which is a 4th generation family business. The owner is a young woman who is friends with Kaz. He said she had been practicing her English and wanted to take half the group through the distillery and the other half would do the tasting and then we would reverse. It is not a big place so that worked well. And she did a good job with her English. This Shochu is only made here on this island and is the oldest of the 27 saki companies. The guide’s great grandfather started the company and it has been family owned since then. Only 6 people work there and run the entire operation. The liquor is similar to a scotch and two of the types were 40 proof and one was 30 proof. Not my style but it was fun to see and taste. It is made from rice, a mold that helps it ferment and both white and brown sugar.

After the tour and tasting, we returned to the ship for a 3:30 PM departure. Our next port is Kagoshima, Japan.

So interesting!

LikeLike